This activity has received funding from the European Institute of Innovation and Technology (EIT). This body of the European Union receives support from the European Union's Horizon 2020 research and innovation programme.

TAKEOFF

Collaborative Design-Build-Operate Ecosystem for optimal simulation-aided equipment selection

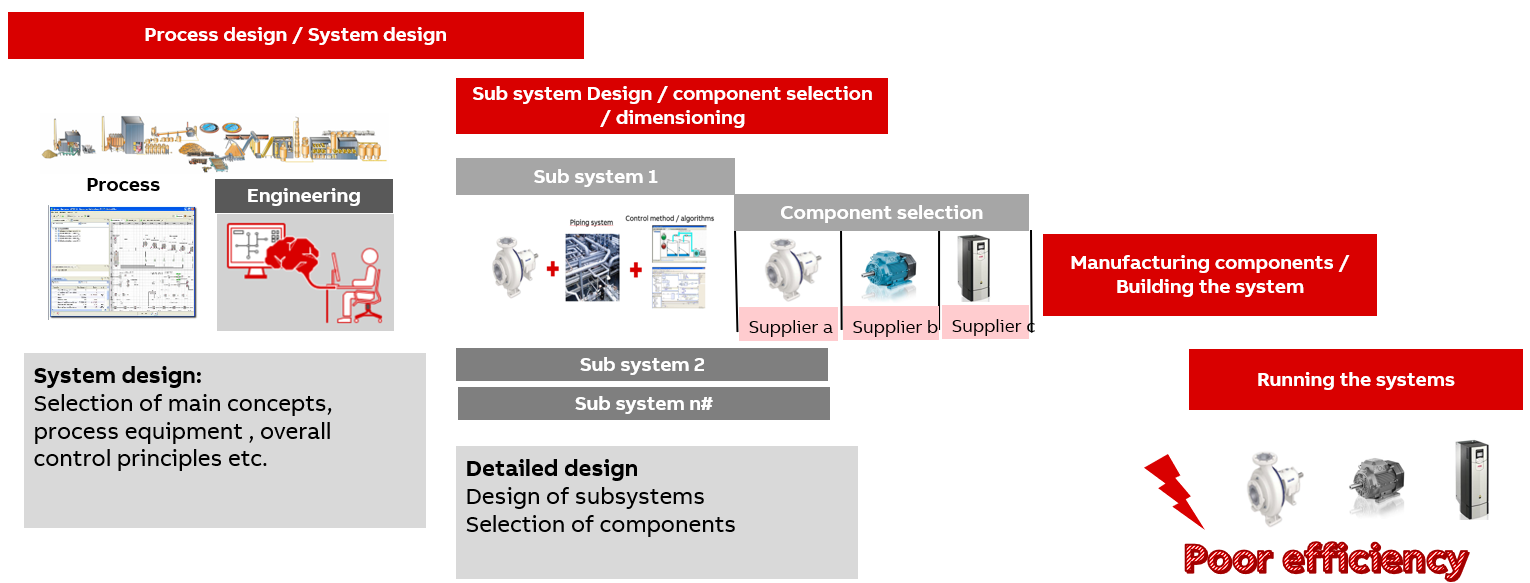

Current process plant design practices follow a waterfall engineering approach in which each process subsystem is designed and dimensioned separately. Among other issues, this engineering flow causes that the safety margins of every process component stack up, resulting in equipment over dimensioning. Moreover, due to the lack of flexibility of current design practices, optimal component selection based also on environmental footprints or maintainability aspects is not possible. Consequentially, oversized, and non-optimal process components are selected and then run inefficiently.

TAKEOFF Approach

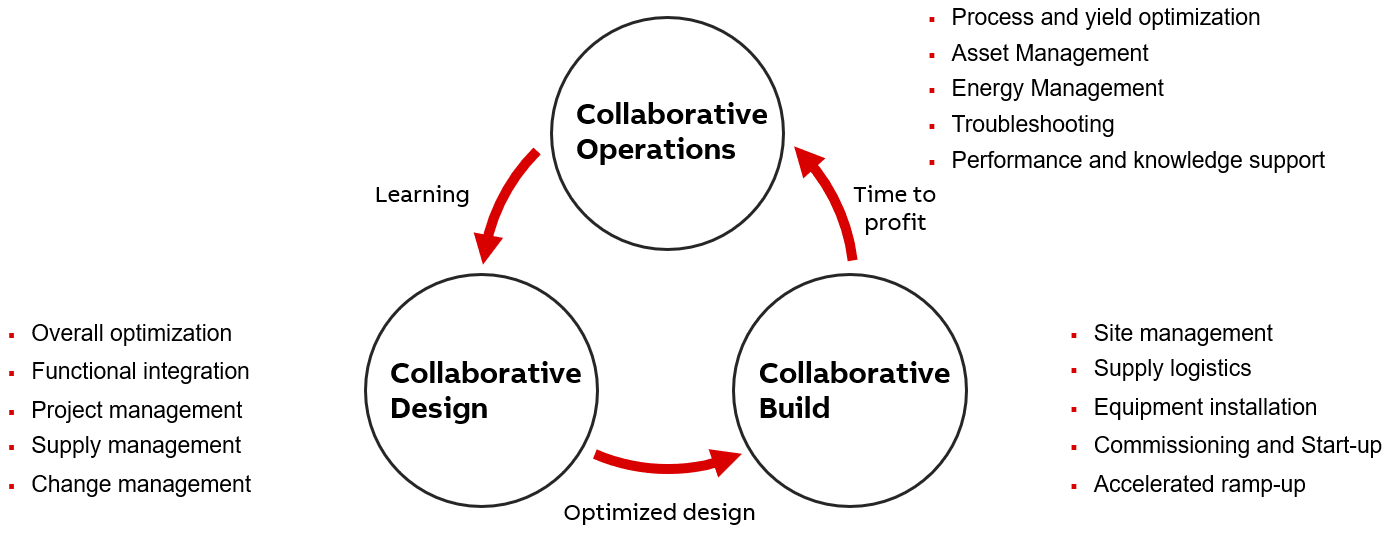

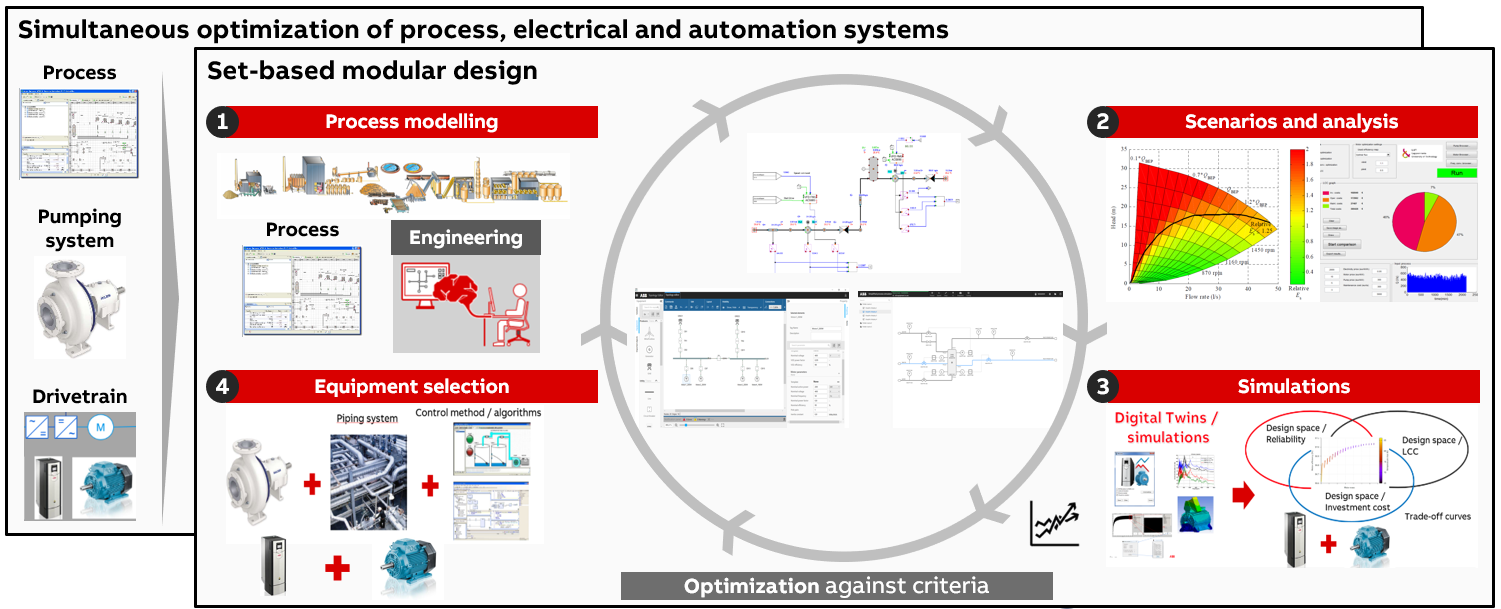

TAKEOFF defines a totally new design ecosystem model where different partners involved in plant engineering can collaboratively design the targeted plant. This new approach, called Collaborative Design-Build-Operate ecosystem, is based on an open, flexible, and privacy-preserving cloud environment that relies on system-wide simulation to offer optimal selection of different process equipment.

The Collaborative Design-Build-Operate ecosystem integrates different simulators (e.g. process simulators and powertrain simulators) with control systems for finding optimal combinations of process components through optimization. The Collaborative Design-Build-Operate ecosystem coordinator can manage multiple parallel simulation iterations for exploring different equipment configurations and modifications efficiently. During these iterations, partners can easily test different scenarios to asses various design aspects such as maintainability of the plant equipment as well as their efficiency.

The Collaborative Design-Build-Operate ecosystem is a powerful solution for collaborative design and optimal selection of plant equipment. It can be applied for greenfield projects where optimal process equipment selection can be assessed before the actual plant is built. This approach can also be used in brownfield projects where process renewal or reconfiguration requires optimal selection of new equipment based on existing data of the plant performance.