A Simulation-Based Digital Twin of production plants

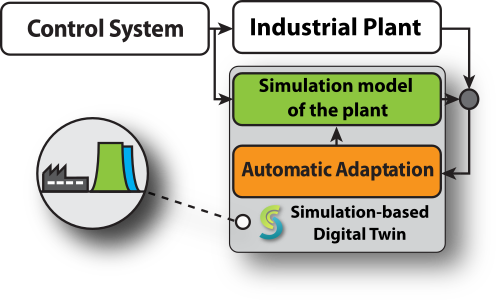

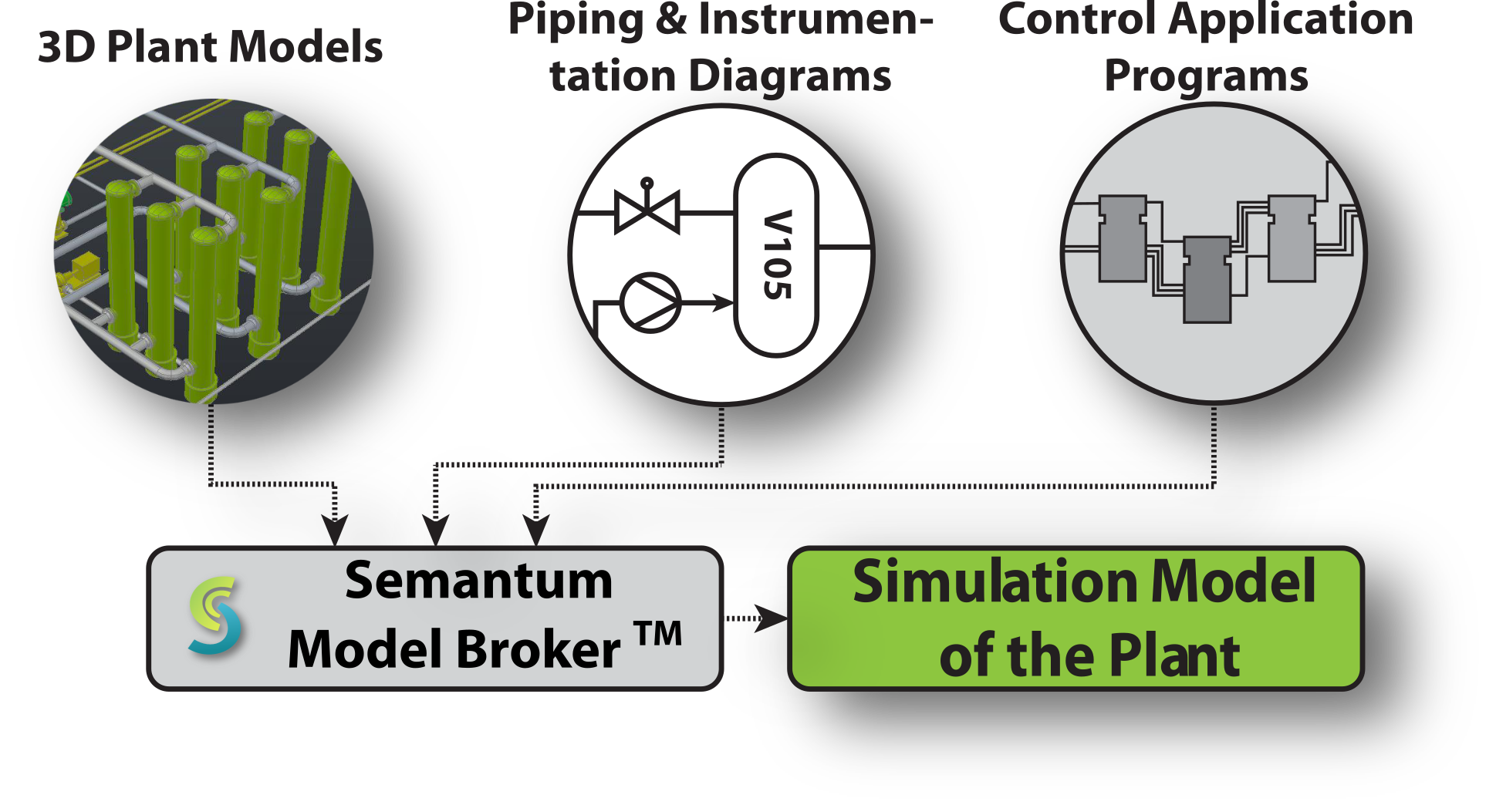

A Simulation-Based Digital Twin is a digital replica of the physical assets of an industrial plant which contains both, the structure and the dynamics of how the devices or process operate.

Digital Twins are a promising application for decision support of modern facilities that can be used for efficient support of operational plants.