Dynamic optimization toolset for efficient tuning and optimization of simulation models

Development of the simulation model corresponds to roughly 40% of the total time required for delivering an

industrial operator training simulator. A big part of this work is targeted to validate and tune the model. This

is required to increase the fidelity of their results. It is a procedure in which the model parameters are

iteratively adjusted until the behavior that best represents the physical system is found. This laborious task

requires domain expertise to select and adjust specific model parameters.

Process modeling requires much knowledge on process, chemical, physical and control. Even though skilled

engineers create models, it takes time to tune the models to improve their fidelity.

Semantum and Omega simulation have collaborated to develop a model optimization toolbox to

efficiently optimize and tune simulation model parameters.

The optimization function calculates the steady state optimal parameter values like cost minimum or benefit

maximization. Similarly, these functions calculate the dynamic optimization like transient state optimization or

minimal time control

with process constraints. These constraints are called simulated constraints. The optimization functions can

also be used for finding optimal PID control parameter.

On the other hand, the tuning functions are to tune systematically and automatically using multi-parameter

optimization methods. The multi-parameter optimization is based on fitting simulation results with the available

measurement data of the target system. This critically reduces time needed for model tuning and can be used to

find optimal parameter values that fit both steady state and dynamic behavior.

The co-developed tool reduces the tuning cost and contributes to develop high-fidelity process model.

The optimization algorithm was developed for tuning the process model and both steady state and dynamic optimization of plant operation. The tool can efficiently determine

the optimal parameters with only a few iterations.

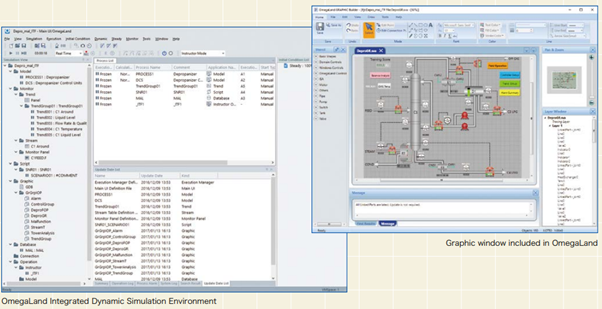

The optimization toolbox has been integrated with Omega Simulation’s product Visual Modeler and some of these

features are planned to be included in the product as an optional function. Visual Modeler is a next-generation

plant simulation tool developed for delivering operation training solutions, for developing control systems, and

for creating online simulation systems for operation support.

Both steady-state and dynamic optimization have been achieved. The high-fidelity model for dynamic process

response is particularly crucial for plant operation and control. Additionally, there are no restrictions on

the process model, as the toolbox functions with the process simulator as a black box.

The optimization toolbox is a comprehensive tool set that aims to reduce development time and effort for model

parameter tuning and finding optimal operation. This results, for example, in shorter development of operator training simulators and other

simulation-based applications. It increases the level of fidelity of

simulation models and plant dynamic optimization.