With a fleet of dozens of power plants across ten countries, operation and production optimization of power

and heat production is critical for Fortum. Efficient operation planning becomes more challenging considering the ever-changing

weather conditions and the constant fluctuations in power price and fuel costs.

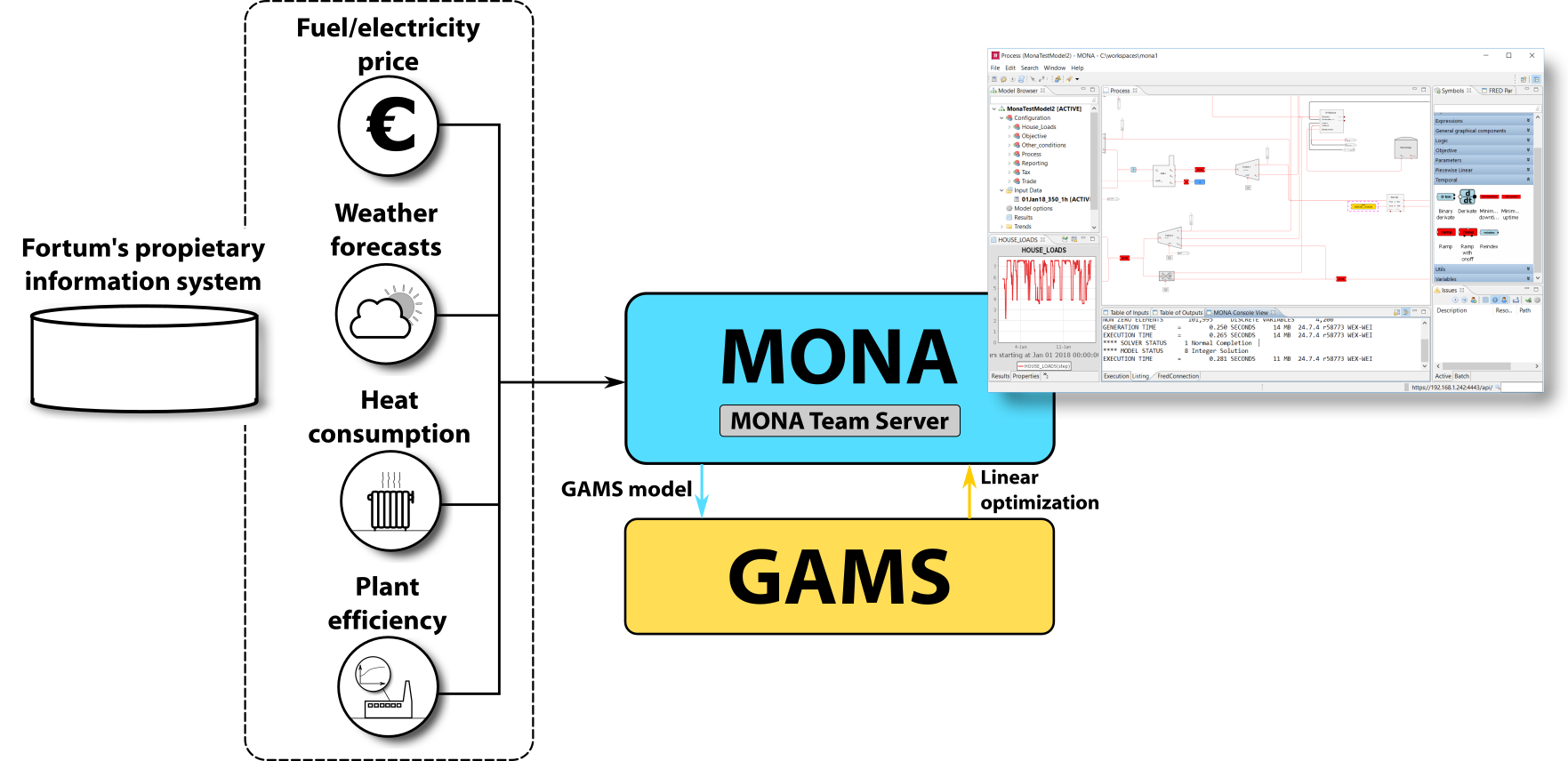

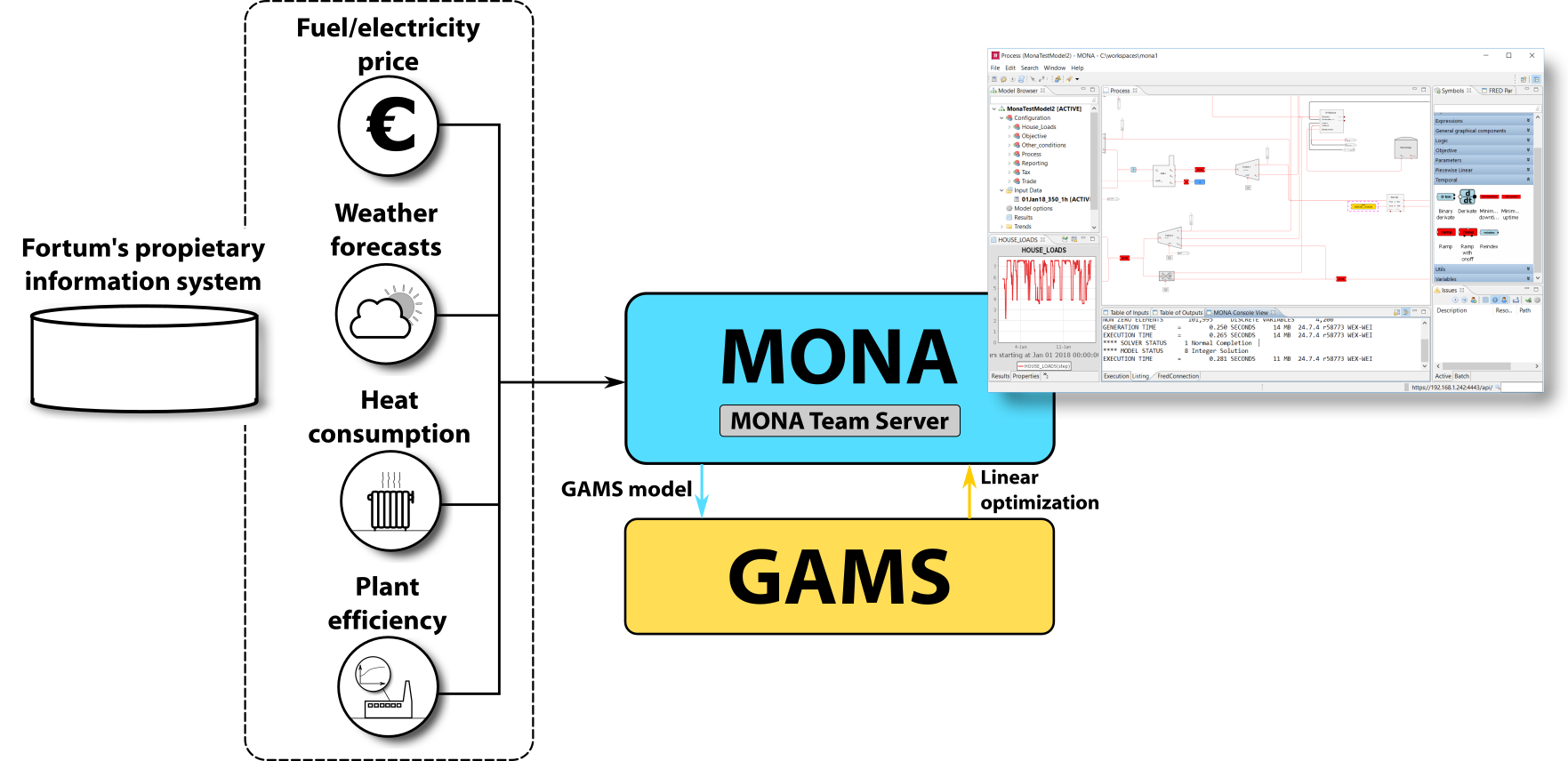

In order to help overcoming this challenge, Semantum together with Fortum have developed MONA,

a mixed integer linear programming modeling tool for optimization of operations. MONA enables rapid and efficient modeling

for performing time-dependent linear optimization based on GAMS system. In MONA, optimization of the operation can be carried

out considering various data sources such as power price, weather forecasts, expected fuel costs, efficiency of different plants

and other consumption parameters.

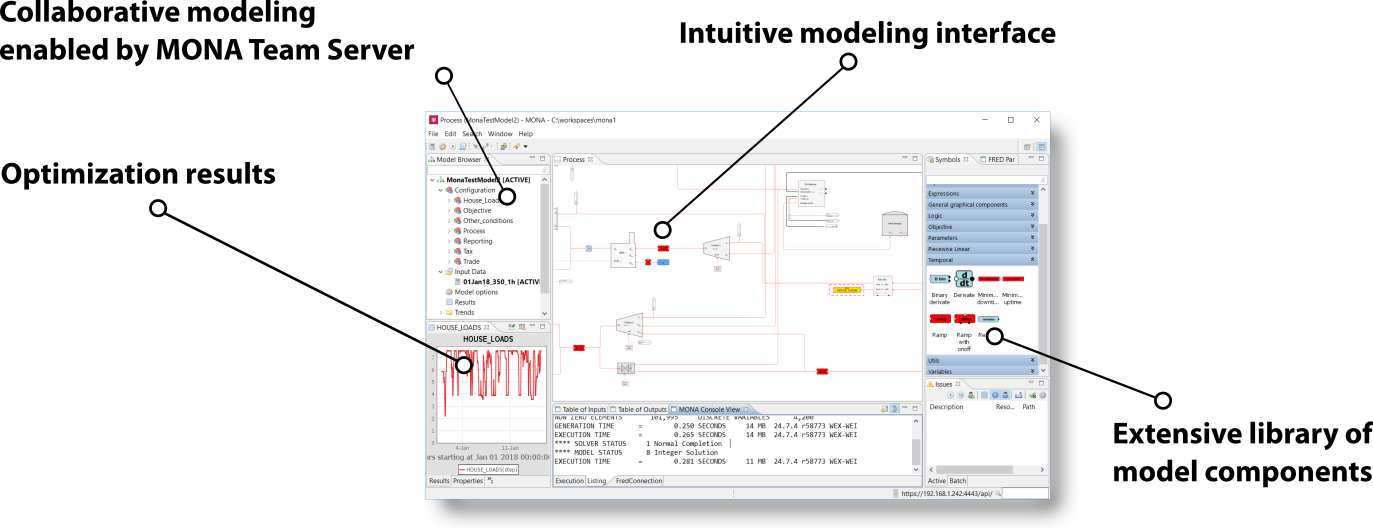

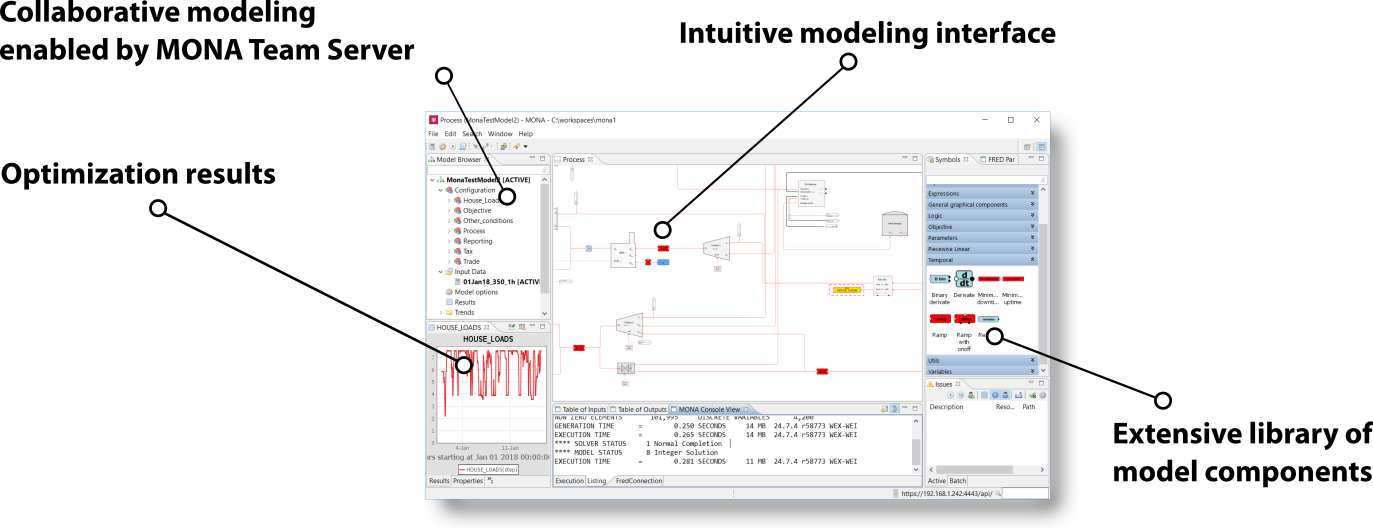

Rapid and efficient modeling enabled by graphical intuitive user interfaces and collaborative modeling features

MONA user interface is based on Simantics platform. In MONA, modeling for linear optimization

is carried utilizing user-friendly graphical interfaces that reduce modeling effort to dragging, dropping, connecting

and configuring model components. This is particularly useful, as MONA users do not necessarily require thorough knowledge

of the underlying model equations.

User-defined model components can be created and then added to the MONA standard components library for

hierarchically composing system models in a fast manner. In addition to speeding up the modeling process, this approach also

increases the understanding and correctness of the models created.

Faster model development is also achieved by collaborative features, enabled by MONA Team Server.

MONA includes team features capabilities such as version management as well as change tracking and reporting. MONA team features

allow efficient collaboration between modeling and optimization teams.

At Fortum, MONA is used across the System Optimization team members to develop and maintain their

linear optimization models. MONA also serves as a back-up system for optimization and it is in active use in other parts of the

organization.