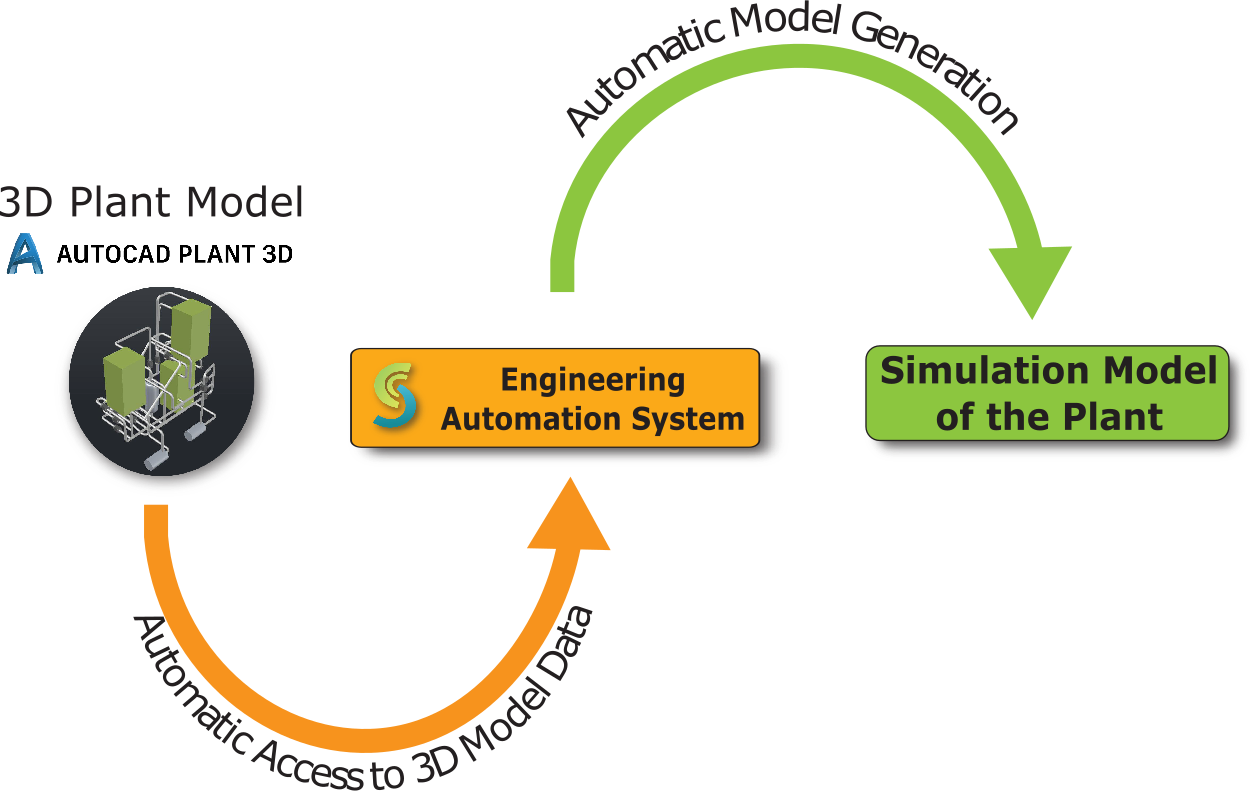

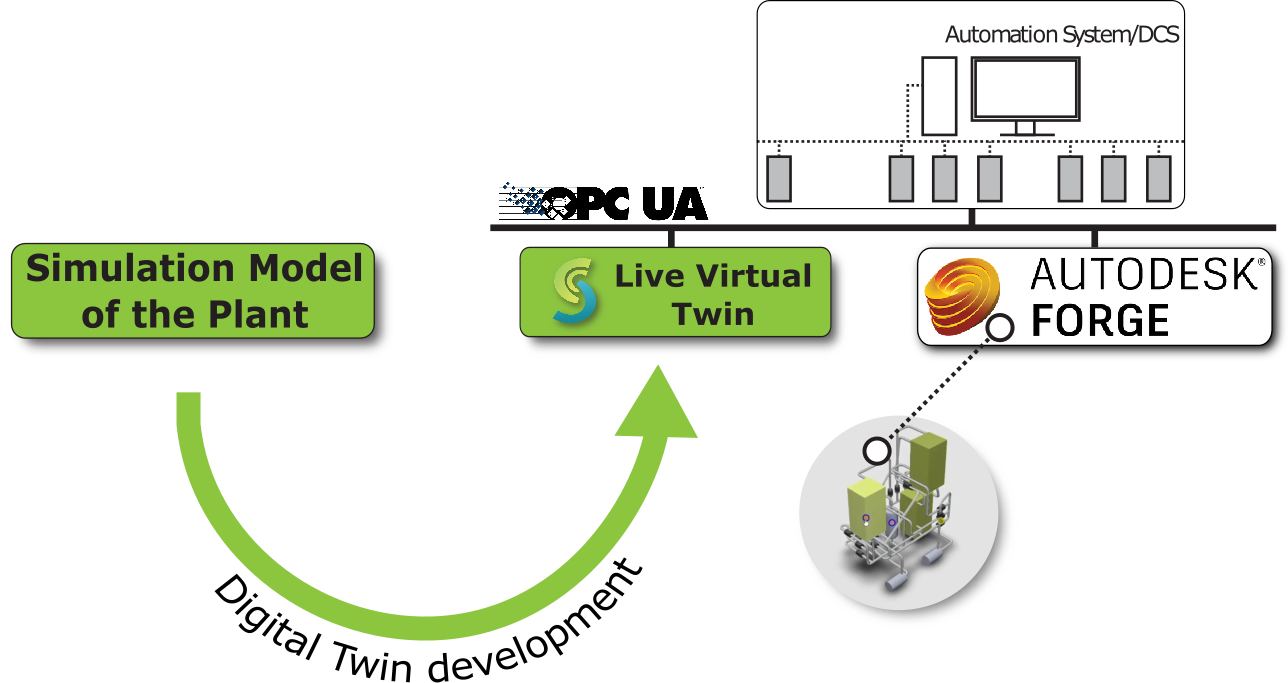

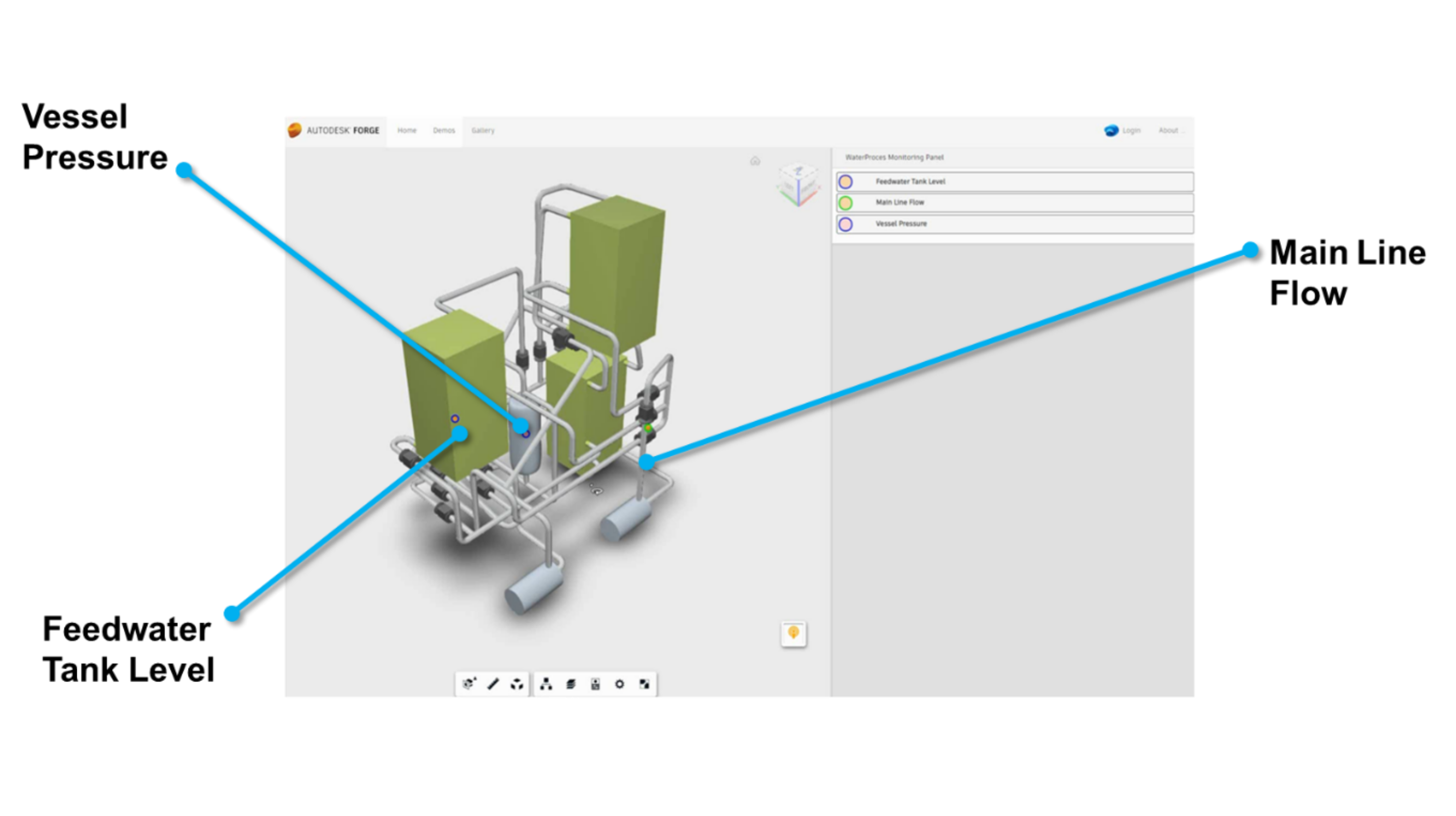

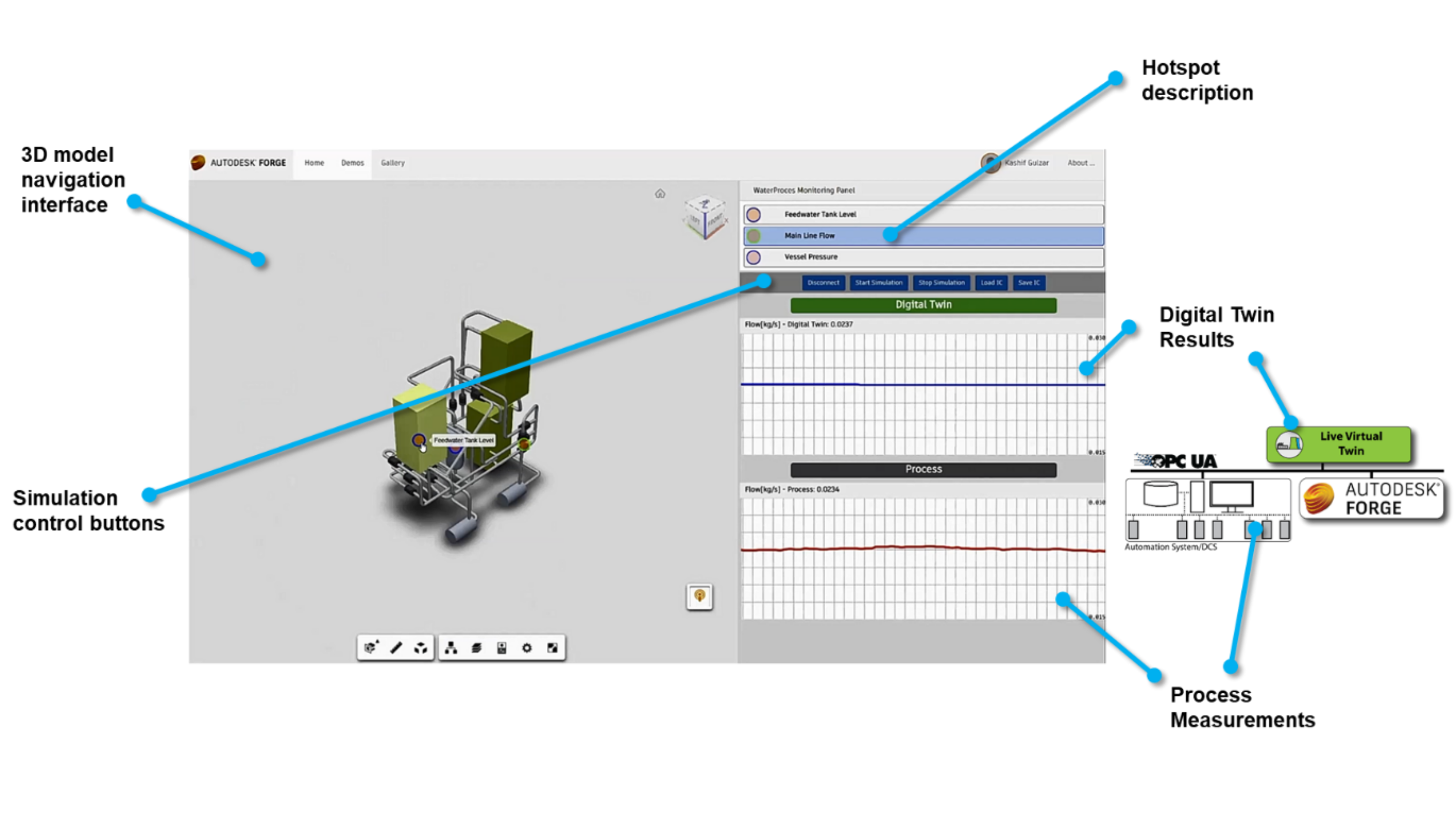

Autodesk is one of the world’s leading CAD/CAM software companies. Autodesk develops software tools extensively used in process industry, such as AutoCAD Plant 3D, a software tool for creating P&IDs and 3D models of production plants. Autodesk also develops Forge, a platform of web service APIs for integration of Autodesk components into web or mobile applications.

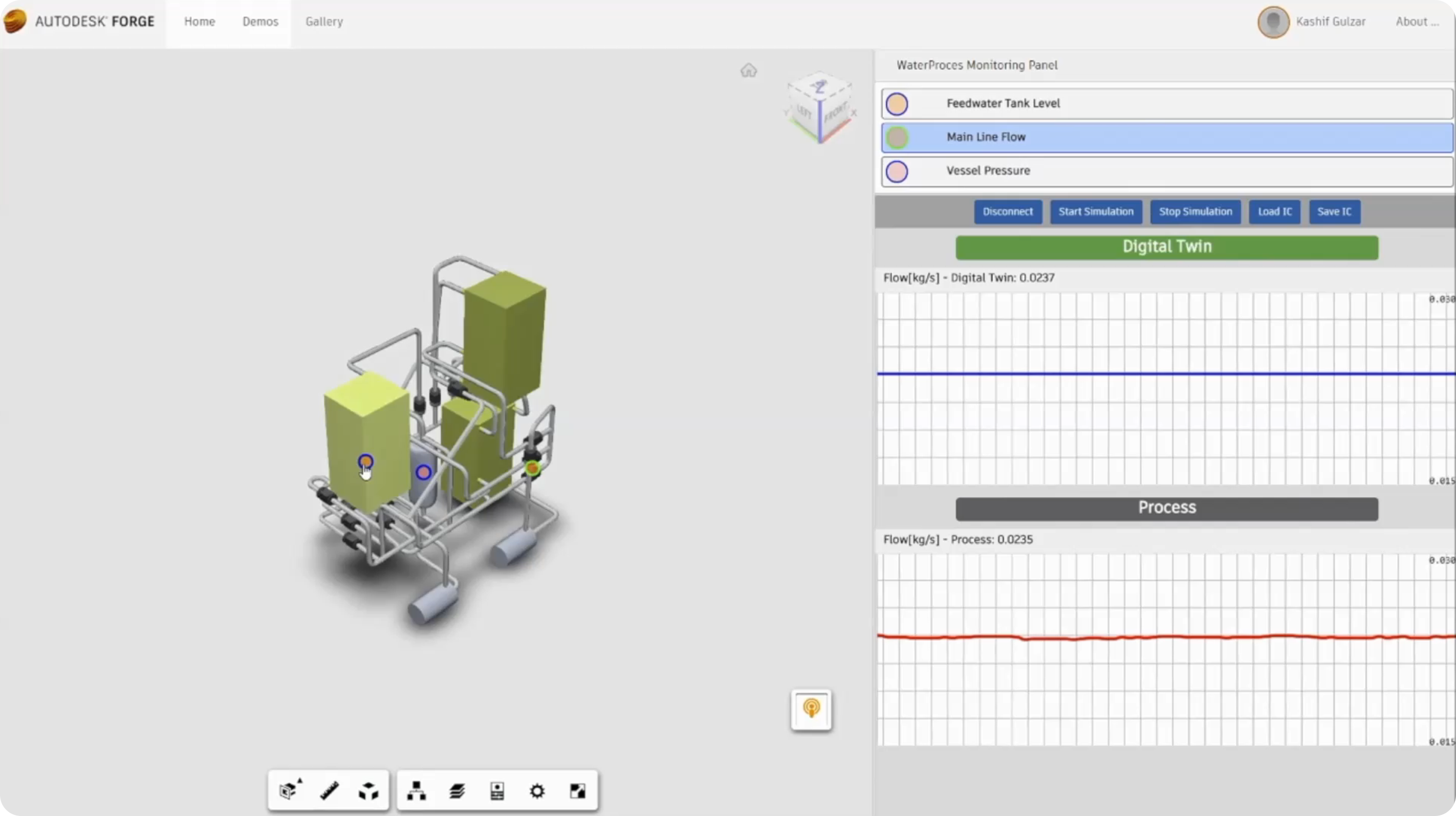

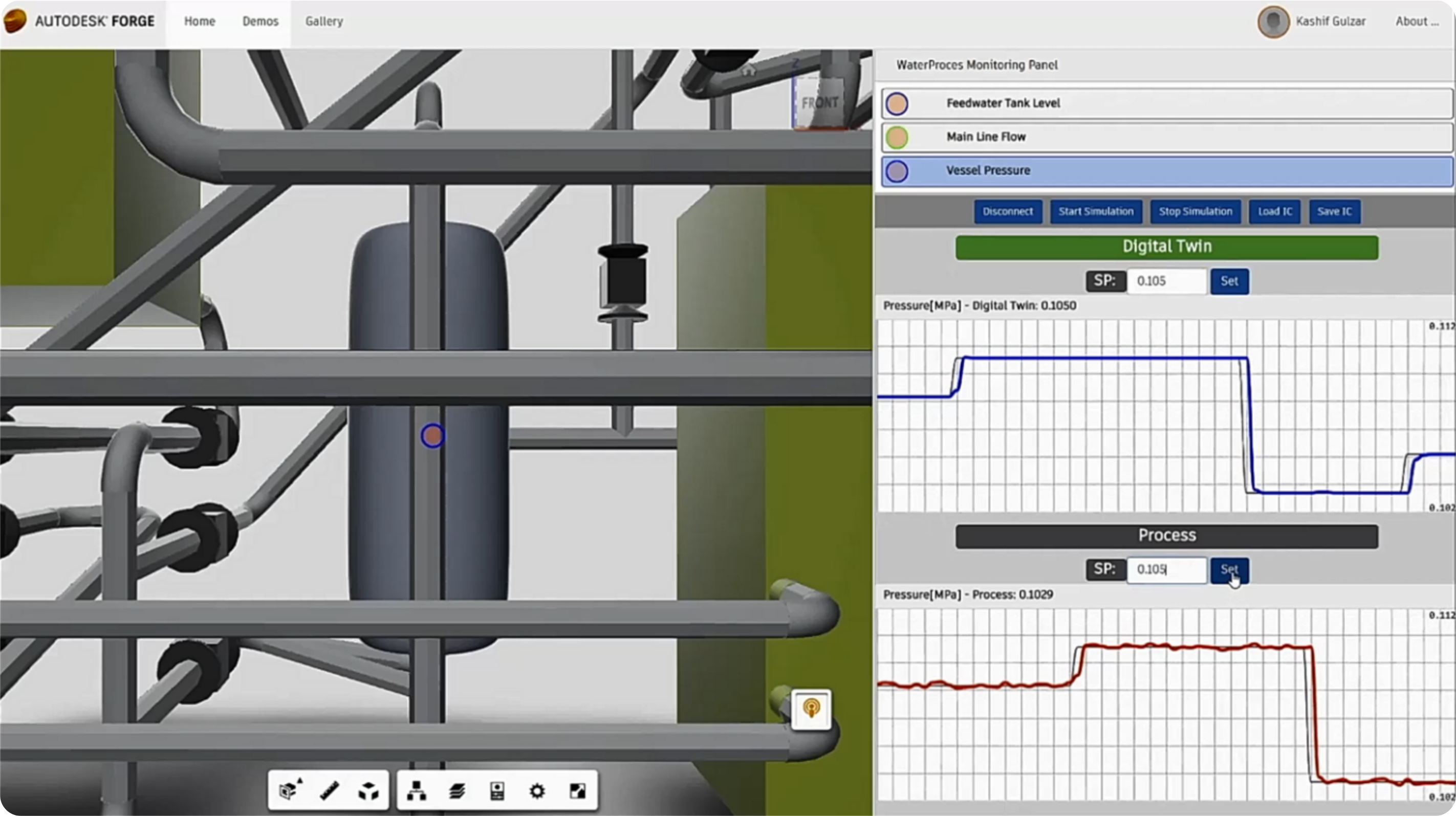

To show the power of the Forge platform we wanted to demonstrate how easy is to build a Digital Twin which is connected to its twin in reality. Semantum has knowledge and experience in simulation, especially with Simantics and OPC UA which allowed them to build the Digital Twin Showcase based on Forge. Semantum did not only build the Digital Twin, they also did a research project with a pilot plant to show the benefits and possibilities of a Digital Twin. The biggest benefit of this type of a Digital Twin is the predictability of the plant behavior during operation: any change of the parameters controlling the plant can be examined before execution.